The world’s most meaningful problems are more complex than ever, likely solvable not by the singular focus of an individual but by the diversified talents of a team. Because of that, unique collaborations between industry and our nation’s land-grant institutions are ever more crucial to fostering scientific creativity and advancing innovation.

For the past year and half, Delaware-based DuPont has been working with student engineers at Virginia Tech in a partnership that gives undergrads fulfilling their senior design requirement real-world experience and gives the science and agriculture giant the ability to nurture the next generation and better understand the future of crop-protection application.

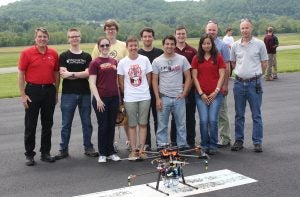

Larry Gaultney, a Senior Engineering Associate with DuPont, worked closely with Tech’s Dr. Kevin Kochersberger, an Associate Professor of Mechanical Engineering, and a small handful of the more than 400 students in the college’s senior class. Each senior teams up with three to seven fellow students and fulfills a capstone project — they build something, make sure it’s functional, and showcase the product in a demonstration.

“We reached out to industry to help us define those capstone projects,” Kochersberger said, noting that DuPont was one of the first companies to get on board with the school’s industry-driven initiative. “We were very happy that they were able to conceive of a useful project for the students.”

DuPont helped to guide the students toward the creation of a scouting and application drone, one that could have a modular payload to allow an imaging system to be put on for scouting while later allowing a sprayer to be attached and used for the targeted application of pesticides.

“The senior design project was a good platform because the students showed an interest in the project, and Kevin had a good group of students,” Gaultney said. “So we launched out on this project together, scoped it out so that it was meaningful — meaningful for them but also from the corporate standpoint. We were interested in learning from this venture.”

While the direction of the project was narrowly defined, the final product was left to the creativity of the young engineering team. Simply put, the challenge was to use a single UAV platform — and all the relevant hardware and software — to be able to fulfill multiple tasks.

Tech is one of the nation’s premier engineering schools and has experience with fixed-wing aircraft as well as vertical takeoff and landing aircraft. Some parts were purchased for a hexacopter design, and the team worked partly off a design that other students had done the previous year. But the large portion of the hexacopter arose from scratch, with frames, support structure, and other pieces fabricated in a lab using 3-D printing. All of the electronics, including software that can handle the higher-level processing that’s going on during image analysis, was custom made.

There were conference calls between DuPont engineers and the Tech students every couple of weeks, where feedback was given.

“A great thing is that the design has got room for growth,” Kochersberger said. “We’re upgrading the onboard imaging system and can incorporate other electronics for data acquisition or processing or image collection.”

The students created a hexacopter that successfully demonstrated the intended imaging and application capabilities. They took ownership of the work, and met and surpassed the challenges that engineering projects in the real world would throw at them. For example, they regularly discussed the project with real customers like Gaultney, and they were met with supply issues, such as lead times on obtaining parts.

“They get to this point in the year, when they have everything built, and they’re now in the testing phase. And this is where they learn the real lessons of life,” their professor said. “They built something that they thought was going to work, and maybe it doesn’t. I always tell the students that they should embrace failure, and this is their last chance to make a mistake and not have an employment outcome result from it. Take advantage of that because we learn from our mistakes. …

“This project is a totally open-ended problem to solve, and how they solved it is determined by their team, and how complete and successful they’re going to be is up to them.”

The collaboration has been so successful that DuPont kicked in funding last summer to support a Virginia Tech grad student to collect imagery. That summer work grew into a graduate project that ultimately involved multiple departments at the university.

“We tried to make it very realistic, that when they were successful, they would know that this was more than just an academic exercise. This was something that could really meet a need in the real world, in agriculture,” Gaultney said.

Nobody expects DuPont, which is currently in the midst of a merger with Dow Chemical Co., to ever sell or service UAVs; what they did directly glean is knowledge of how crop protection can be employed in years to come.

But more than that, the underlining partnership with a land-grant university like Virginia Tech means so much for agriculture and the future of those who could work in the industry.

“I was very impressed with the level of professionalism and the quality of work that the students did,” Gaultney said. “This was a remarkable team.”