Did you know that nearly 60 percent of sugar in the U.S. comes from beets?

Yes, it’s true! So many people think of sugarcane when it comes to sugar, but a majority actually comes from this massive crop seen here:

One acre of beets can yield a whopping 30 tons of beets! Minnesota and North Dakota are two states that lead the country in sugar beet production. Perhaps you’ve even heard of the American Crystal Sugar Company?

Fortunately I was in their area recently, and the people there gave me a tour of the production facility! And, boy, is it fascinating. Of their five plants in the Red River Valley area of Minnesota/North Dakota, I toured one of their smaller plants — even so, it produces about 2.5 million pounds of sugar per day!

After sugar beets are unloaded at the factory, they’re washed, and the rocks and weeds are sorted out.

Next, the beets are sliced into what’s called “cosettes” which are like shoestring potatoes or potato chip type shapes. This factory processes and turns around about 300 tons per hour.

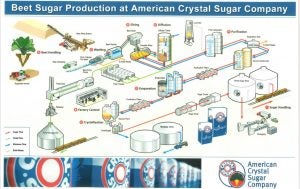

When sugar beets are harvested, they start out at around 75 percent water. Without making the process sound overly complicated, really the goal is to reduce the water content and extract the sugar through the very impressive process shown below:

Diffusion, remove impurities, dry the pulp, evaporation, crystallization, boiling, pulverizing, storage, etc., etc. This is what the beets look like after they’ve been dried up a bit:

When it comes to the breakdown of a sugar beet, about 18 percent of the beet is sugar, 5 percent is called “Marc” as livestock feed, and the rest is water that’s extracted and recycled.

Ever seen animal feed that looks like this in pellet form?

It’s a byproduct from … you guessed it, sugar beets! Sometimes molasses from cane sugar can also be added to sweeten the feed.

This factory tour ends up making powered sugar, brown and white granulated sugar, sugar syrup, livestock feed, and other products. There are many aspects of purification from lime and pH balance to laboratory testing. Yes, there is a lot of science and chemistry that goes into sugar production! This shows a part of that where liquid sugar impurities are tested and separated:

Sometimes when you buy juice drinks they’ll say, “made from natural sugar,” but the way this liquid sugar is made traditionally here would not be considered “natural” on the label.

What is your thoughts on this crash course in sugar production? I love when brands show transparency. I want to give special thanks to Curt Hansen and his team for showing me around this plant in Moorhead, Minnesota! If you’re ever in the area, consider taking a tour for yourself, as they do them quite regularly. The more we understand food production, the more likely we will become comfortable with the process and appreciate where it comes from.

Michelle Miller, the Farm Babe, is an Iowa-based farmer, public speaker, and writer, who lives and works with her boyfriend on their farm, which consists of row crops, beef cattle, and sheep. She believes education is key in bridging the gap between farmers and consumers.