As farming evolves alongside technology, maximizing yields is as important as ever. When it comes to harvest optimization, Bushel Plus has emerged as a leader in the space. Already building a track record of success in its early stages, Bushel Plus customers have reported annual grain savings of $10,000 to $100,000 in one season with their suite of products.

Growing up on a small farm in western Indiana, I remember how much time went into the fall harvest, particularly in terms of setting up the combine. With the technology available today, farmers help reduce waste due to overlooked moisture content and evident grain wastage, both during harvesting and storage.

Bushel Plus was founded as a Canadian company in 2016, ideas born of a German farm boy’s love for agricultural engineering has resulted in a suite of smart products designed to reduce harvest waste in terms of bushels per acre, reduce volunteer weeds, and improve combine loss sensor calibrations so as to add value and profit to every inch of ground farmed. In a nutshell, the whole goal is to save producers time, energy, and money.

Bushel Plus products are exported in more than 35 countries, with a dominant market share in Canada and Australia, and continued growth into the U.S. Between the SmartPan System™, the MAD Concaves™, the MiniCombine™, and the Grain Shaker Box™, Bushel Plus’s products can help every farmer seeking to increase yields and reduce grain loss.

The Bushel Plus SmartPan System™

With the Bushel Plus SmartPan System™, the days of sifting and counting grain on the ground or dangerously throwing a pan beside the combine are no longer. To truly understand grain loss out the back of the combine, a safe and accurate method of weight measurement is needed. Combines have had loss sensors for years, but they must be calibrated properly to get the full picture of how much grain is being lost at any sensitivity setting. This is especially important for combine automation, where we can lose productivity based on these settings if we don’t have a proper understanding of losses.

The Bushel Plus SmartPan System™ comes in three sizes, the 60”, the 40”, and the 20” to fit the needs of the famer, with the 40” system being their best seller for the majority of crops, harvest modes, and use cases. The system works in conjunction with a remote control or their SmartDrop App to drop the pan remotely off the back of the combine. The magnetic drop pan attaches to the combine with dual magnets within seconds so there’s no wiring or bolts necessary. And every farmer knows the value of time savings here with no additional tools needed to attach the magnetic unit.

The system collects grain samples of any kind that are then cleaned in a matter of seconds using the Bushel Plus Air Separator and then weighed using the provided scale. The SmartDrop app provides quick and accurate loss analysis without the need for any manual calculation. The real eye opener in the app is its ability to present real data on dollar per hour and dollar per acre loss so farmers can truly understand the impact on profits. Quick changes to combine settings from there can reduce losses and make a big impact on the bottom line of any farm operation.

Each system comes with:

- Carrier unit which attaches to the combine

- Short stubble drop pan (large)

- Long stubble drop pan (small)

- Air Separator

- Digital field scale

- Smart charger

- User manual and reference guides

- SmartDrop App

The SmartDrop app offers measurements, in both imperial and metric units, and allows you to save your best combine settings for future reference, share the results, as well as access combine tips and industry-certified loss analysis data.

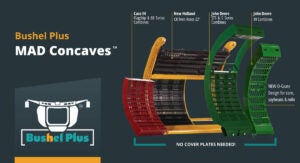

The Bushel Plus Mad Concaves™

Designed with the goal of getting more quality grain in the bin while maximizing combine capacity, the MAD Concaves™ are available for both the John Deere STS/S and X9 Series, Case IH Flagship and 88 Series, and the New Holland CR 22” Rotor series combines. Instead of the traditional round wire combine concaves, these units are designed with a bar-and-grate style that helps get more grain out of the head faster and therefore more into the hopper for less rotor loss and dockage. Even better, due to their modular frame and inserts design, the concave inserts can be swapped out quickly and easily, which means one person can swap concaves of an entire combine in 10 to 15 minutes. This is unheard of and brings many more benefits to the farm when it comes to ease of maintenance and leveling of concaves.

The MAD Concaves™ are manufactured with high-quality AR-200 (abrasion-resistant) steel and come in custom grate spacings and designs to get the best possible results in any crop or threshing conditions. The MAD Concaves™ O-Grate concave is an innovative design for corn, soybeans and milo. Other specialty designs include the Finger Grate Concave, which is designed for the front position and works great with edible beans, canola, and sunflower and the Alfalfa Grate, which is the only specialized concave on the market specific for alfalfa. Meanwhile the .435, also a larger grate spacing model, works in either the first or second position and is ideal for thresh crops like hemp, chickpeas, and faba beans. The .225 Concave works in the front position and is designed to reduce dockage with hard thresh crops like wheat, flax, and canary seed.

MAD Concaves™ are customized to the combine and the crop, ensuring there is one to fit your every need. What’s great is that these parts are all simple to use, with the overall goal being a savings of time, energy, and money.

Bushel Plus MiniCombine™

Billed as the “World’s Smallest Combine,” the Bushel Plus MiniCombine™ is just downright neat. A portable combine that allows for the precise collection of crop samples directly in the field. The way it’s used in the field reminds one of a hand-held vacuum cleaner. You’ll simply carry it into the field and suck up some samples.

Whether for wheat, barley, canola, sorghum, oats, soya, peas, field beans, or flax, the device saves farmers time and money by leaving the big combine in the barn and simply testing your own crops in the field before deciding when to harvest. As with the rest of the Bushel Plus lineup, it’s easy to use and no tools are required. Every farmer knows the difference moisture content can make at harvest, and with the MiniCombine™ there’s no reason to chance it. The fuel savings along make the MiniCombine™ from Bushel Plus a must have.

Grain Shaker Box™

The grain shaker box™ is a handy tool that fits inside the cab of the combine, truck, or even in your own home. Designed to help you check the grain for quality and cracked kernels, the unit comes with five different slotted plates for work with different sized grains. The whole idea is a quick quality assessment of grain samples to check for cracked grain, white heads, Fusarium, and it can be drawn right from the hopper or grain cart at any point.

Time is Money

Time is a lot like farm ground in that they’re not making any more of it. Thanks to innovations in technology, farmers don’t need to stick a shovel under a combine to measure loss anymore. Not only does this improve on safety, but these handy devices are also time-savers.

I remember my father and grandfather losing hours a day during harvest changing out parts, and how they would go out into the field and hand-test the moisture content by feel. Now, there are tools that make all that a thing of the past and provide a more precise measurement. Instead of spending half a day swapping out concaves, farmers can now spend just a few minutes. And given how accustomed producers are now to calibrating their sprayers and air seeders, it only makes sense to take the next step and use modern tools to better calibrate their payload — the harvest itself.

NOTE: This is sponsored content produced in partnership with Bushel Plus.